Selecting the Right Marine Fasteners for your Boat

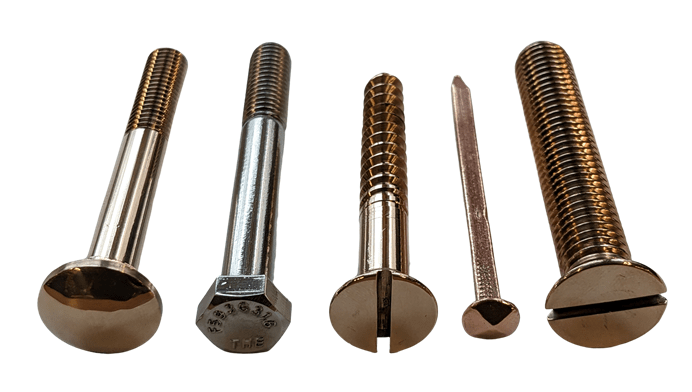

When it comes to boat maintenance, every detail matters—right down to the fasteners (the nuts, bolts, and screws) that hold everything together. Whether you're replacing deck hardware, installing through-hull fittings, or working on your wooden boat restoration, using the right marine grade fasteners can mean the difference between a long-lasting, reliable repair and premature failure or ugly streaks of rust.

If you’ve ever grabbed a handful of stainless steel screws from a big-box store only to find them rusting a season later, you’re not alone. Many boaters don’t realize that not all stainless steel is created equal. Here’s what you need to know about choosing marine fasteners that will stand up to the harsh marine environment.

Why Marine-Grade Fasteners Matter

Boats live in some of the harshest conditions imaginable—constant exposure to salt water, humidity, and fluctuating temperatures. Ordinary hardware store fasteners may look the part, but they often fail when exposed to these elements for extended periods. That’s why serious boat owners and marine professionals rely on 316 stainless steel and silicon bronze fasteners for their projects.

316 Stainless Steel: The Corrosion-Resistant Workhorse

Not all stainless steel is the same. The standard stainless fasteners found in most hardware stores are typically 304 stainless steel, which may work fine in many household applications but is not ideal for a marine environment. Over time, 304 stainless steel can develop rust spots and degrade when exposed to salt water and high humidity.

316 stainless steel, on the other hand, is specifically designed for marine applications. It contains molybdenum, which significantly enhances its corrosion resistance, making it much more durable in saltwater conditions. If you’re securing hardware topside, installing a new anchor roller, or reinforcing your boat’s transom, 316 stainless steel fasteners are the way to go. They offer:

- Superior rust and corrosion resistance

- High strength and durability

- Long-lasting performance, even in saltwater environments

Silicon Bronze: The Time-Tested Favorite for Wooden Boats and Below-the-Waterline Applications

For classic wooden boats, through-hull fittings, and other below-the-waterline applications, silicon bronze fasteners are the gold standard. Silicon bronze has been used in boatbuilding for centuries because of its exceptional corrosion resistance and long lifespan—some fasteners last over 100 years! It also resists galling and seizing, making it easier to work with than stainless steel in many applications.

Boatbuilders and marine professionals favor silicon bronze for:

- Through-hull fittings

- Keel bolts

- Wooden boat construction and repair

- Areas exposed to continuous immersion in water

Unlike stainless steel, silicon bronze won’t suffer from crevice corrosion in oxygen-deprived environments, making it a must-have for any serious boat maintenance project.

Where to Buy the Right Marine Fasteners

If you’re investing in your boat’s longevity, don’t cut corners with subpar fasteners. Fair Wind Fasteners specializes in 316 stainless steel and silicon bronze marine fasteners, ensuring that you get the best quality hardware for your boat. Whether you need hex bolts, carriage bolts, lag screws, or washers, Fair Wind Fasteners has the right products to keep your boat secure and seaworthy.

When you’re out on the water, peace of mind comes from knowing that your boat is held together with fasteners that won’t fail. Choose the right materials, and your boat will thank you for years to come!